Industrial Valves for Camlock Fittings | ProCamlock

Reliable Fluid Control for Demanding Industrial Applications

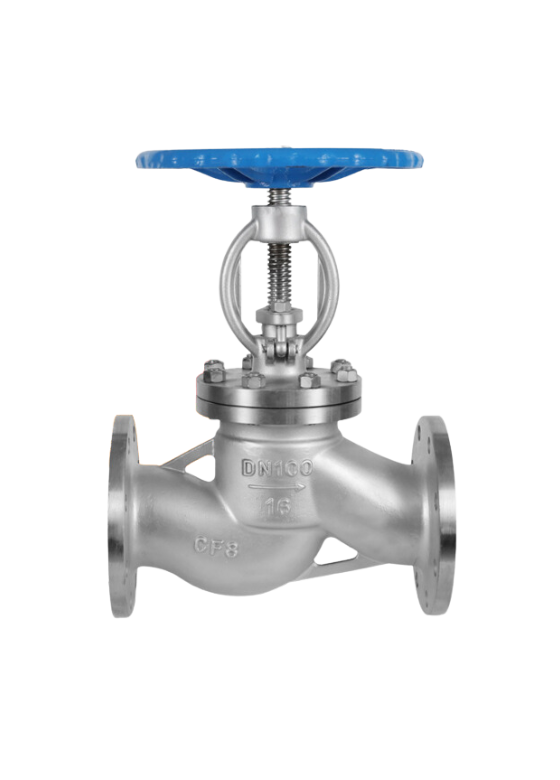

Durability and precision are non-negotiable when it comes to fluid handling in tough industrial environments. ProCamlock, a trusted name in fluid control technology, offers a comprehensive range of industrial valves specifically engineered to integrate seamlessly with Camlock fittings. These valves are designed to meet the rigorous demands of industries such as chemical processing, petroleum, manufacturing, agriculture, and water treatment. valve manufacturer

Why Camlock Fittings?

Camlock (or cam and groove) fittings are known for their simplicity, speed, and leak-free connection. They eliminate the need for tools, making hose and pipe connections faster and more efficient. When paired with high-performance industrial valves, Camlock systems deliver unmatched control and safety for managing various fluids, from water and oil to aggressive chemicals and granulated materials.

ProCamlock’s Industrial Valves: Engineered for Excellence

ProCamlock offers a wide selection of industrial valves compatible with Camlock systems, each crafted with robust materials and precision engineering:

1. Ball Valves

ProCamlock’s stainless steel and brass ball valves provide excellent shut-off control with minimal pressure drop. Designed for quick integration with Camlock fittings, they are ideal for high-pressure and corrosive fluid applications. ball valve manufacturer

2. Gate Valves

For applications that require full-flow control with minimal flow restriction, ProCamlock’s gate valves are a reliable solution. These valves ensure smooth operation and are available in various sizes to suit both low- and high-volume systems.

3. Check Valves

Prevent backflow with ProCamlock’s durable check valves. These valves maintain unidirectional flow and are critical in protecting pumps and preventing contamination in piping systems.

4. Butterfly Valves

These valves offer a lightweight yet rugged option for regulating large volumes of fluid. With a compact design and easy quarter-turn operation, ProCamlock’s butterfly valves pair efficiently with Camlock couplings for fast and secure fluid transfer. butterfly valve manufacturer

Key Features of ProCamlock Industrial Valves

• Camlock Compatibility: All valves are designed to match ProCamlock’s full range of Type A–F cam and groove fittings.

• Heavy-Duty Materials: Constructed from stainless steel, aluminum, brass, and polypropylene for compatibility with a wide range of fluids.

• High Flow Efficiency: Optimized for minimal turbulence and maximum throughput.

• Corrosion & Pressure Resistance: Built to withstand harsh chemicals, extreme temperatures, and high-pressure conditions.

• Quick Installation: Tool-free integration with Camlock systems reduces downtime and increases productivity.

Applications Across Industries

ProCamlock’s valve solutions are trusted in:

• Oil & Gas: Managing fuels, lubricants, and hydraulic fluids safely.

• Chemical Processing: Handling aggressive acids and solvents.

• Agriculture: Irrigation, fertilizer, and pesticide distribution.

• Food & Beverage: Hygienic valves for fluid transfer and cleaning systems.

• Water Treatment: Reliable valves for wastewater and clean water systems.

Why Choose ProCamlock?

With decades of experience and a focus on quality, ProCamlock is a leader in fluid handling solutions. Every product undergoes rigorous testing to ensure compliance with industrial standards and long-term operational reliability. Stainless Steel Ball Valve Manufacturer

________________________________________

Upgrade your fluid control systems today with ProCamlock’s industrial valves – engineered for Camlock compatibility and built to endure the toughest environments.

Explore the full product range at

https://procamlock.com/products/valves-and-filters/industrial-valves/

Industrial Valves for Camlock Fittings | ProCamlock

Reliable Fluid Control for Demanding Industrial Applications

Durability and precision are non-negotiable when it comes to fluid handling in tough industrial environments. ProCamlock, a trusted name in fluid control technology, offers a comprehensive range of industrial valves specifically engineered to integrate seamlessly with Camlock fittings. These valves are designed to meet the rigorous demands of industries such as chemical processing, petroleum, manufacturing, agriculture, and water treatment. valve manufacturer

Why Camlock Fittings?

Camlock (or cam and groove) fittings are known for their simplicity, speed, and leak-free connection. They eliminate the need for tools, making hose and pipe connections faster and more efficient. When paired with high-performance industrial valves, Camlock systems deliver unmatched control and safety for managing various fluids, from water and oil to aggressive chemicals and granulated materials.

ProCamlock’s Industrial Valves: Engineered for Excellence

ProCamlock offers a wide selection of industrial valves compatible with Camlock systems, each crafted with robust materials and precision engineering:

1. Ball Valves

ProCamlock’s stainless steel and brass ball valves provide excellent shut-off control with minimal pressure drop. Designed for quick integration with Camlock fittings, they are ideal for high-pressure and corrosive fluid applications. ball valve manufacturer

2. Gate Valves

For applications that require full-flow control with minimal flow restriction, ProCamlock’s gate valves are a reliable solution. These valves ensure smooth operation and are available in various sizes to suit both low- and high-volume systems.

3. Check Valves

Prevent backflow with ProCamlock’s durable check valves. These valves maintain unidirectional flow and are critical in protecting pumps and preventing contamination in piping systems.

4. Butterfly Valves

These valves offer a lightweight yet rugged option for regulating large volumes of fluid. With a compact design and easy quarter-turn operation, ProCamlock’s butterfly valves pair efficiently with Camlock couplings for fast and secure fluid transfer. butterfly valve manufacturer

Key Features of ProCamlock Industrial Valves

• Camlock Compatibility: All valves are designed to match ProCamlock’s full range of Type A–F cam and groove fittings.

• Heavy-Duty Materials: Constructed from stainless steel, aluminum, brass, and polypropylene for compatibility with a wide range of fluids.

• High Flow Efficiency: Optimized for minimal turbulence and maximum throughput.

• Corrosion & Pressure Resistance: Built to withstand harsh chemicals, extreme temperatures, and high-pressure conditions.

• Quick Installation: Tool-free integration with Camlock systems reduces downtime and increases productivity.

Applications Across Industries

ProCamlock’s valve solutions are trusted in:

• Oil & Gas: Managing fuels, lubricants, and hydraulic fluids safely.

• Chemical Processing: Handling aggressive acids and solvents.

• Agriculture: Irrigation, fertilizer, and pesticide distribution.

• Food & Beverage: Hygienic valves for fluid transfer and cleaning systems.

• Water Treatment: Reliable valves for wastewater and clean water systems.

Why Choose ProCamlock?

With decades of experience and a focus on quality, ProCamlock is a leader in fluid handling solutions. Every product undergoes rigorous testing to ensure compliance with industrial standards and long-term operational reliability. Stainless Steel Ball Valve Manufacturer

________________________________________

Upgrade your fluid control systems today with ProCamlock’s industrial valves – engineered for Camlock compatibility and built to endure the toughest environments.

Explore the full product range at https://procamlock.com/products/valves-and-filters/industrial-valves/