How Does Jiko's Automation Enhance Pre-Roll Infusion

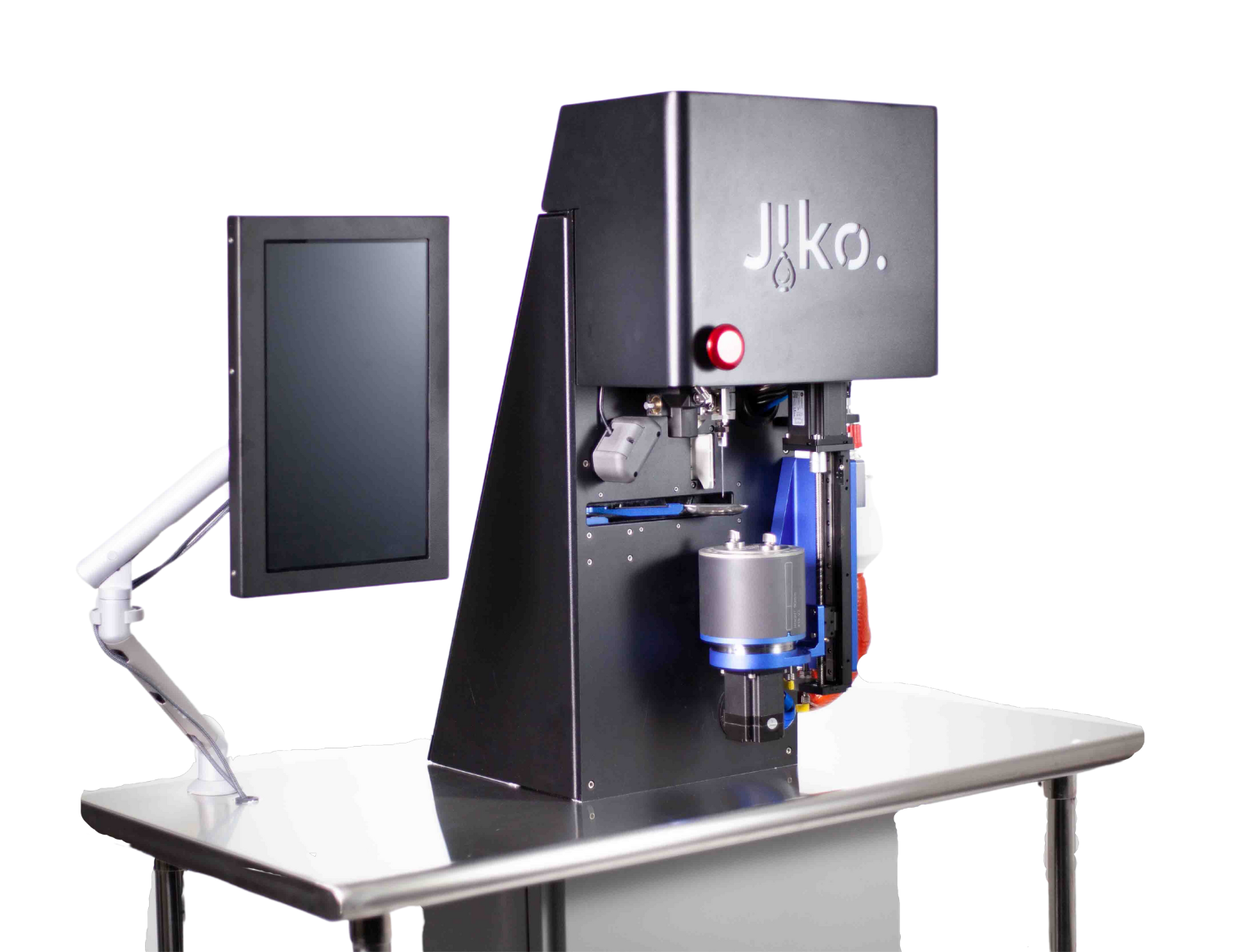

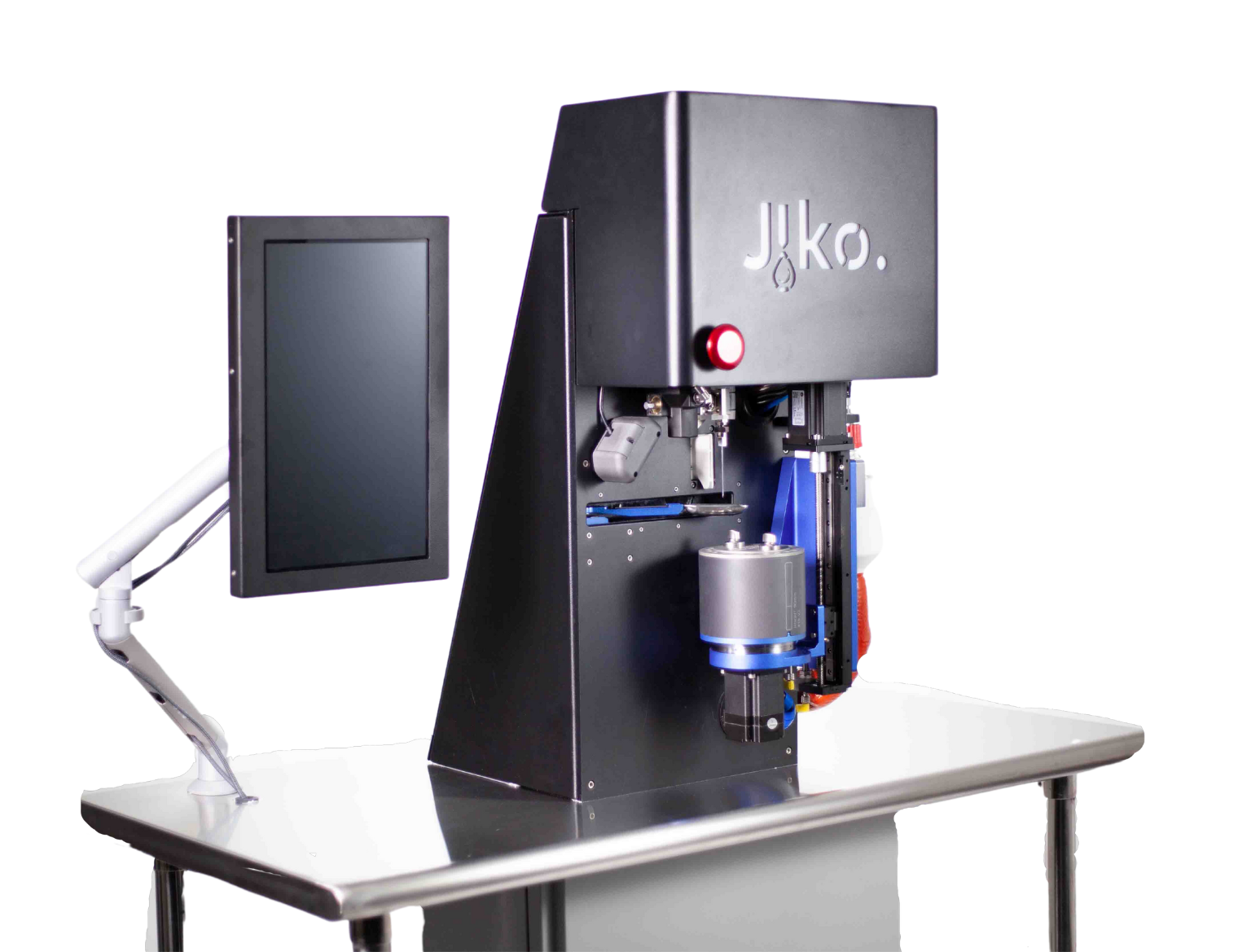

The Jiko Automated Pre-Roll Infusion Robot is a technological advancement that is revolutionizing the cannabis pre-roll manufacturing process. By automating the infusion of extracts into pre-rolls, it elevates production efficiency, consistency, and product quality while reducing operational costs and manual labor. Sortingrobotics designed Jiko to address the growing demand for reliable and scalable pre-roll infusion solutions. This article explores how Jiko’s automation enhances pre-roll infusion, breaking down the technical advantages and the broader impact on the cannabis industry.

With the increasing demand for high-quality infused pre-rolls, manufacturers are seeking innovative solutions to scale production without compromising on quality. Jiko’s automation addresses these industry needs by combining precision engineering with advanced robotics, setting a new standard for reliability and output in pre-roll manufacturing.

Understanding Pre-Roll Infusion

Pre-roll infusion refers to the process of adding concentrated extracts such as cannabis oils, distillates, or other active ingredients into pre-rolled cannabis cigarettes. This infusion enhances the potency, flavor, and overall consumer experience of the pre-roll product. Traditionally, pre-roll infusion has been a labor-intensive, manual procedure prone to inconsistencies and inefficiencies.

Manual infusion methods often require precise handling, skilled labor, and slow production speeds. The inherent variability in manual processes can result in uneven distribution of concentrates, leading to inconsistent dosing and quality. Additionally, manual infusion limits scalability due to the time and cost associated with labor.

Automation and Its Role in Modern Pre-Roll Production

Automation in manufacturing has become essential for increasing throughput and maintaining product uniformity. The cannabis industry is no exception. Pre-roll production demands precise infusion techniques, and automation addresses several key challenges that manual processes face.

Automated systems bring controlled precision to concentrate application, enabling consistent dosing and reducing human error. This precision directly improves product quality, which is critical for meeting regulatory standards and consumer expectations. Moreover, automation enhances production speed, enabling manufacturers to meet growing market demand more efficiently.

Jiko’s Automation Technology: Key Features

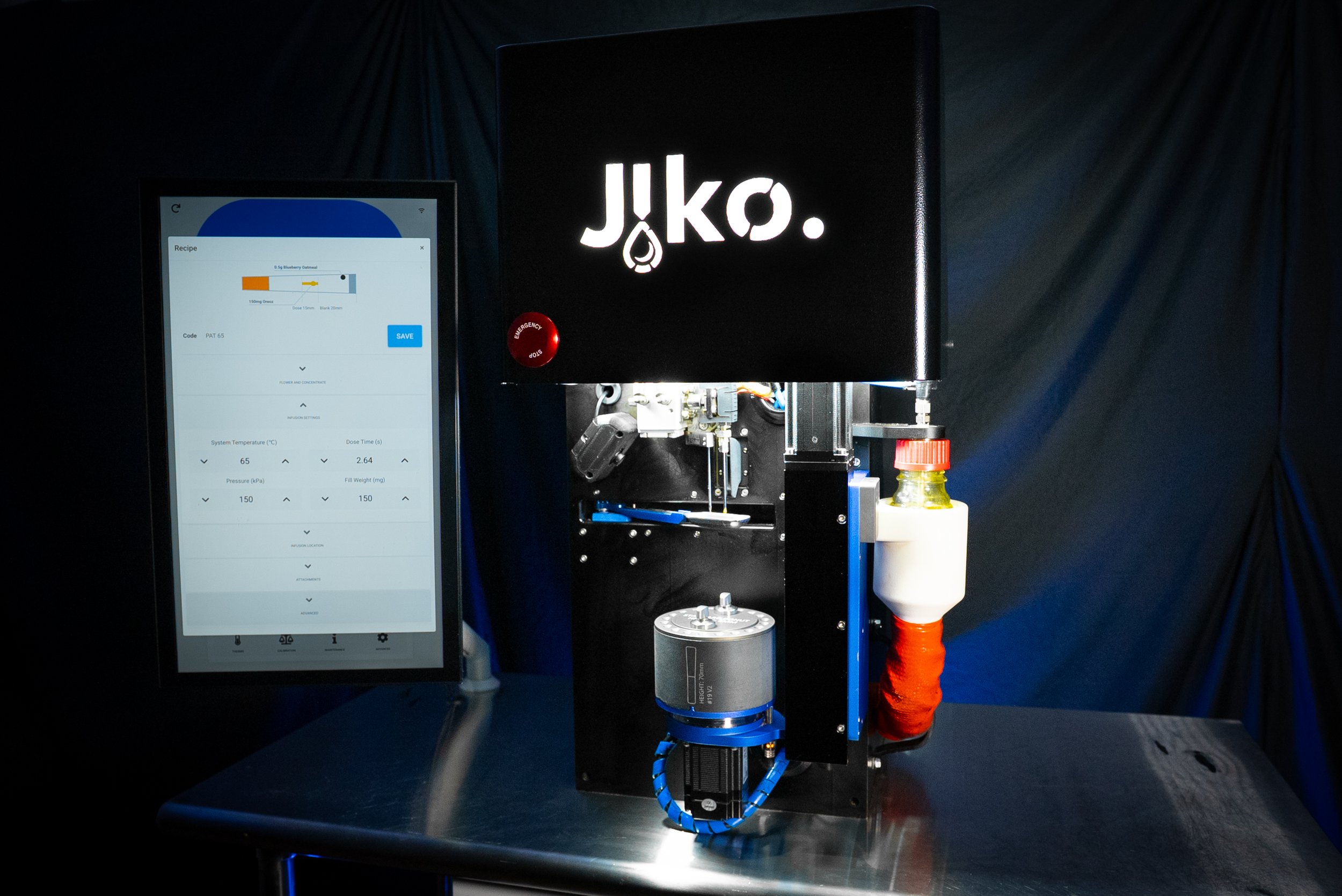

Jiko stands out in the field of automated pre-roll infusion because of its innovative approach and specialized design. Its automation system integrates robotics, advanced sensors, and precise dosing technology to streamline the infusion process. The key features of Jiko’s automation include:

-

High-Precision Dosing: Jiko utilizes finely calibrated dosing mechanisms that ensure exact amounts of extract are infused into each pre-roll. This reduces waste and guarantees consistent potency across batches.

-

Robotic Handling: The robotic system carefully manages pre-rolls during infusion to maintain structural integrity and prevent damage, a common issue in manual handling.

-

Scalable Throughput: Designed for commercial production, Jiko supports high-volume manufacturing, making it suitable for brands aiming to scale their pre-roll output.

-

Real-Time Quality Monitoring: Integrated sensors and software continuously monitor infusion quality, allowing for immediate adjustments and ensuring each product meets strict standards.

-

User-Friendly Interface: Jiko’s control panel simplifies operation, enabling quick setup and easy integration into existing production lines.

Enhancing Efficiency and Consistency

One of the most significant advantages of Jiko’s automation is the dramatic improvement in production efficiency. By mechanizing the infusion process, manufacturers can significantly increase output rates compared to manual infusion. This acceleration reduces lead times and allows companies to respond faster to market demand.

The consistent dosing capability of Jiko also ensures that every pre-roll infused delivers a uniform experience. This uniformity is essential not only for consumer satisfaction but also for compliance with cannabis regulations, which often require precise cannabinoid content labeling. Automated infusion minimizes the risk of product recalls or regulatory fines that can arise from inconsistent dosing.

Reducing Labor Costs and Increasing Safety

Manual pre-roll infusion requires skilled laborers who must carefully apply extracts to avoid damaging the product or causing inconsistent dosing. This labor is costly, prone to human error, and can lead to ergonomic injuries over time due to repetitive motions.

Jiko reduces these labor demands by automating repetitive tasks, lowering the need for human intervention. This automation translates into lower labor costs, fewer workplace injuries, and increased operational safety. Staff can focus on overseeing the process and quality control rather than on manual infusion work.

Impact on Product Quality and Innovation

Automated pre-roll infusion allows manufacturers to experiment with different infusion formulas and patterns, pushing product innovation forward. Jiko’s precise control over dosing enables customization of potency levels and the incorporation of multi-extract blends, providing a competitive edge in a crowded market.

Moreover, by ensuring the integrity of pre-rolls during infusion, Jiko helps maintain the product’s physical quality—preventing unraveling or damage that could negatively affect consumer perception. The consistency and reliability brought by automation ultimately foster greater brand trust and consumer loyalty.

Integration with Existing Manufacturing Lines

Jiko’s design facilitates seamless integration into existing cannabis pre-roll manufacturing lines. Its compact footprint and modular components enable manufacturers to add automated infusion capabilities without disrupting current workflows. This adaptability makes it an attractive option for businesses at various stages of scale and automation readiness.

The system’s software can interface with production management tools, providing valuable data on output rates, product quality, and material usage. This data integration supports informed decision-making and continuous process improvement.

Environmental and Operational Sustainability

Beyond production benefits, automation technologies like Jiko contribute to operational sustainability. By precisely dosing concentrates, the system minimizes material waste. Reduced waste not only saves costs but also decreases the environmental footprint of pre-roll manufacturing.

The reduction in manual labor and increased efficiency mean that energy consumption per unit produced is lower. Sustainable manufacturing practices are increasingly valued by consumers and regulators, positioning automated infusion as a future-forward choice for cannabis producers.

Conclusion

Jiko’s automation significantly enhances pre-roll infusion by improving precision, consistency, and efficiency. Through advanced robotics and dosing technologies, it overcomes the limitations of manual infusion, reduces labor costs, and supports scalability. The benefits extend beyond operational improvements to product quality, regulatory compliance, and sustainability. As the cannabis industry continues to evolve, automation solutions like Jiko represent a critical step toward optimized manufacturing and innovative product development.

FAQs

What types of extracts can Jiko infuse into pre-rolls?

Jiko is compatible with a variety of cannabis concentrates including oils, distillates, and other liquid extracts. Its dosing system can be calibrated to handle different viscosities and formulations to meet specific product requirements.

How does Jiko ensure consistency in dosing?

Jiko uses precision dosing mechanisms controlled by robotics and sensors that measure the exact amount of concentrate for each pre-roll. Real-time monitoring adjusts for any deviations, ensuring uniform potency.

Can Jiko be integrated into existing production lines?

Yes, Jiko is designed for easy integration with current pre-roll manufacturing setups. Its modular design and software compatibility allow seamless addition without major workflow disruptions.

How does automation with Jiko improve workplace safety?

By automating repetitive and manual infusion tasks, Jiko reduces the risk of ergonomic injuries and exposure to concentrates. Operators focus on quality control rather than physically intensive processes.

What impact does Jiko have on production speed?

Jiko significantly increases infusion throughput compared to manual methods, enabling higher volume production and faster fulfillment of market demands.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness