Robotic Welding Market is driven by Precision Welding

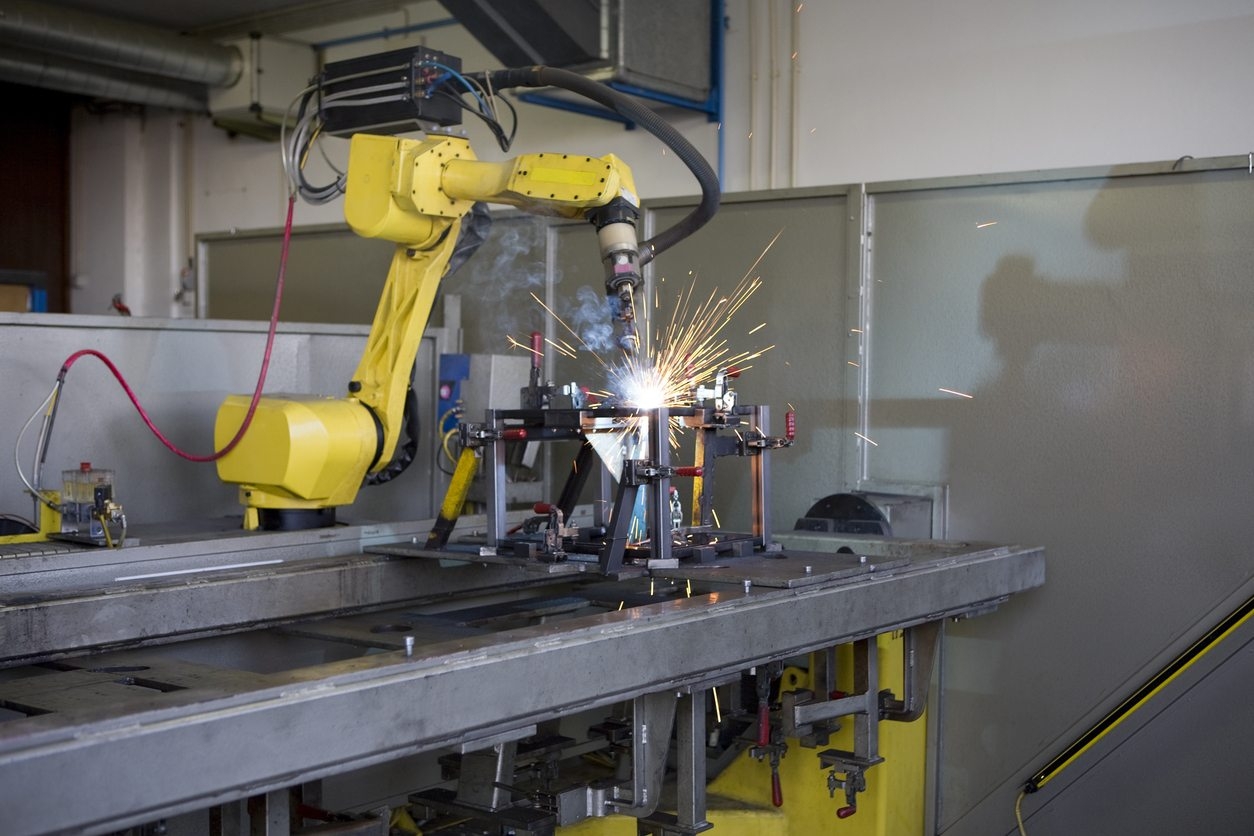

Robotic welding integrates programmable robots with welding power supplies to automate and optimize joining processes across a wide range of industries. By combining sensors, manipulators, and advanced control systems, robotic welding cells deliver repeatable precision, reduced cycle times, and minimal human exposure to fumes and arc radiation. These systems support MIG, TIG, spot, laser, and plasma welding techniques, allowing manufacturers to tailor configurations to specific material thicknesses, joint geometries, and tolerance requirements. The adoption of collaborative robots (cobots) has further lowered barriers to entry by offering safety features that permit human–robot interaction in shared workspaces. Robotic Welding Market advantages such as consistent weld quality, lower rework rates, and enhanced throughput make robotic welding indispensable in automotive assembly, heavy machinery fabrication, shipbuilding, and aerospace manufacturing. In addition, integration with digital platforms—through Industry 4.0 protocols, real-time monitoring, and predictive maintenance—enables enterprises to track key performance indicators and optimize resource utilization. As labor shortages and quality standards tighten, manufacturers increasingly turn to robotic welding solutions to uphold competitiveness, meet regulatory mandates, and scale production flexibly.

According to CoherentMI, The robotic welding market is estimated to be valued at USD 10.48 Bn in 2025 and is expected to reach USD 20.95 Bn by 2032, growing at a compound annual growth rate (CAGR) of 10.4% from 2025 to 2032.

Key Takeaways

Key players operating in the Robotic Welding Market are

Yaskawa Electric Corporation,

Kuka AG, ABB Ltd.,

Panasonic Corporation,

Fanuc Corporation.

These industry leaders invest heavily in R&D to refine robot kinematics, welding torch stabilization, and intuitive programming interfaces. Strategic alliances with system integrators, software developers, and end-use sector champions bolster their ability to deliver turnkey solutions, drive aftermarket support, and expand service networks. By offering modular platforms that accommodate payloads from a few kilograms to over 500 kg, these key players cater to diverse applications—from microelectronics welding to large-scale structural steel assembly.

Get More Insight On: Robotic Welding Market

Get this Report in Japanese Language: ロボット溶接市場

Get this Report in Korean Language: 로봇용접시장

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness