Industrial Automation Market Size, Share & Research Report 2032 | UnivDatos

Introduction: Automation as the Backbone of Modern Manufacturing

Industrial automation has become a cornerstone of modern manufacturing, significantly reshaping global production landscapes. As industries strive to reduce costs and improve operational flexibility in increasingly competitive environments, automation technologies have moved from optional upgrades to strategic imperatives. With the rapid integration of artificial intelligence (AI), the Internet of Things (IoT), and robotics, the industrial automation market is undergoing a revolutionary transformation.

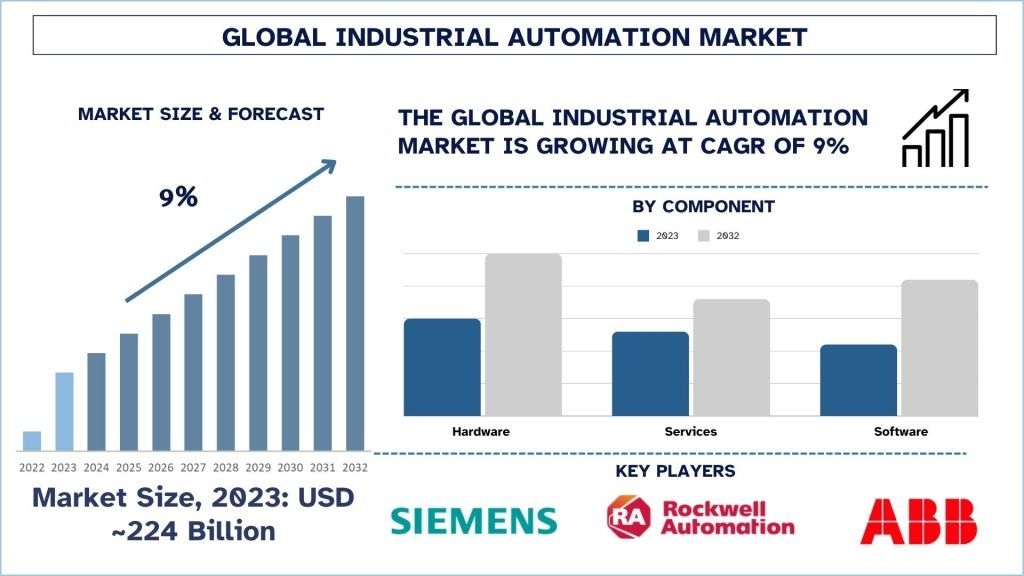

According to UnivDatos, The global industrial automation market was valued at USD 224 billion in 2023, and is projected to grow at a CAGR of approximately 9%, reaching new highs by 2032. This growth is driven by the expansion of Industry 4.0, accelerating industrialization in emerging markets, a surge in labor shortages, and increasing demand for intelligent and connected automation solutions.

Access sample report (including graphs, charts, and figures): https://univdatos.com/reports/industrial-automation-market?popup=report-enquiry

AI-Powered Automation: Redefining Industrial Efficiency

Artificial intelligence is playing a central role in the evolution of smart manufacturing. Through machine learning and data-driven optimization, AI enables factories to enhance decision-making, implement predictive maintenance, and increase overall system autonomy. Industrial robots powered by AI are now capable of learning from historical data, reducing machine downtime, and improving accuracy in complex production tasks.

In a recent milestone, Schaeffler and Siemens signed a memorandum of understanding (MoU) at Hannover Messe 2024 to further integrate AI in automation. Their joint development, the Siemens Industrial Copilot, demonstrates how AI-based industrial systems are setting new benchmarks in performance and collaboration.

Companies like Siemens, ABB, and Rockwell Automation are at the forefront of these advancements, particularly in high-precision industries such as automotive, pharmaceuticals, and electronics—key sectors within the discrete automation market.

The IoT Revolution: Connecting Devices for Smarter Factories

The Internet of Things is another game-changing technology shaping the industrial automation market. By connecting machines, devices, and sensors, IoT facilitates real-time monitoring and control, enabling predictive analytics and adaptive decision-making in manufacturing systems.

In smart factories, IoT devices monitor parameters like temperature, vibration, and output rates—delivering actionable insights that help manufacturers optimize operations and reduce downtime. This trend is especially impactful in the automation control components and devices market, where sensor-equipped machinery enhances connectivity and agility.

Cobots: Redefining Human-Robot Collaboration

Collaborative robots—or cobots—are revolutionizing the workplace by working safely and efficiently alongside human employees. Unlike traditional robots that require safety barriers, cobots are equipped with sensors and AI, allowing them to operate in shared environments with precision and adaptability.

In 2024, major companies launched next-generation cobots to expand their industrial applications:

- FANUC unveiled a new lineup of cobots and controller technologies at IMTS 2024.

- OMRON Automation introduced the TM S Series in India, featuring improved safety and joint flexibility.

- Schneider Electric launched the Lexium Cobot, combining cutting-edge robotics and automation.

- ABB expanded its cobot portfolio with GoFa™ and SWIFTI™, targeting higher payloads and faster operation.

SMEs, in particular, are expected to increase cobot adoption due to their affordability and ease of integration into existing workflows, especially in discrete automation market segments like electronics assembly, packaging, and component manufacturing.

Edge Computing: Real-Time, On-Site Intelligence

Edge computing is transforming how automation systems process data by bringing computation closer to the data source. In manufacturing, this translates to faster response times, reduced reliance on centralized data centers, and improved operational efficiency.

This technology is a natural complement to IoT and AI, as it empowers smart devices and systems to make immediate decisions. The implementation of digital twins and real-time analytics is particularly beneficial in industries such as chemicals and automotive, where rapid adjustments and control precision are critical.

5G Connectivity: Unlocking Next-Gen Automation

The deployment of 5G networks is unlocking new levels of responsiveness and scalability in industrial environments. High bandwidth, ultra-low latency, and support for massive device connectivity make 5G a powerful enabler for seamless automation.

In 2024, advancements in 5G are facilitating smoother machine-to-machine communication, reducing delays, and enabling the real-time synchronization of distributed systems. The aerospace, automotive, and pharmaceutical sectors are among the early adopters leveraging 5G for mission-critical automation tasks.

Sustainability and Energy-Efficient Automation

Sustainability has emerged as a core driver in automation strategy. Manufacturers are turning to energy-efficient technologies and automation systems to reduce environmental impact and meet global regulatory requirements. From smart motors to intelligent energy management systems, green automation is transforming how resources are utilized.

Automation solutions also enable optimized material usage, reduced waste, and accurate emissions tracking—features that align with broader corporate social responsibility (CSR) goals and consumer preferences for eco-conscious production practices.

Click here to view the Report Description & TOC https://univdatos.com/reports/industrial-automation-market

Conclusion: The Future of Smart Manufacturing

The industrial automation market is evolving rapidly, shaped by cutting-edge technologies and rising global demand for productivity, accuracy, and sustainability. Innovations in AI, IoT, cobots, edge computing, and 5G connectivity are redefining manufacturing processes and paving the way for the factories of the future.

As businesses embrace these trends, the integration of intelligent systems and digital infrastructure will be key to remaining competitive in the global economy. The growth of the automation control components and devices market and the discrete automation market signifies a broader movement toward smarter, more agile, and environmentally responsible industrial ecosystems.

Organizations that invest in these forward-looking technologies today will be best positioned to thrive in the transformative decade ahead.

Related Industry Reports-

India Metaverse Market : Current Analysis and Forecast (2024-2032)

India AR/VR Market: Current Analysis and Forecast (2024-2032)

Large Language Model Market: Current Analysis and Forecast (2024-2032)

India MSME Payment Risk Management Solution Market: Current Analysis and Forecast (2024-2032)

AI Data Center Market: Current Analysis and Forecast (2024-2032)

Contact Us:

UnivDatos

Contact Number - +1 978 733 0253

Email - contact@univdatos.com

Website - www.univdatos.com

Linkedin- https://www.linkedin.com/company/univ-datos-market-insight/mycompany/

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness